How Does A HVAC System Work?

September 21, 2015

Your HVAC system is the core of heating and cooling within your home. If you get a high-quality system, you’re never going to feel uncomfortable at the height of summer or in the dead of winter. So how does one of these systems work?

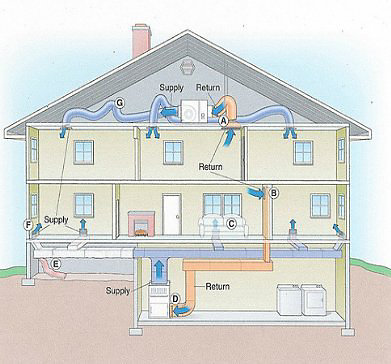

Heating and Cooling Distribution Systems

It’s important to understand how different heating and cooling distribution systems work. This will help you to better understand your HVAC system.

Forced Air Systems – The forced air system takes hot or cold air and forces it through metal ducts using a blower. Hot air is forced through one set of ducts and cold air is sent through another set of ducts, depending on whether you’re using the air conditioner or the furnace.

The most common problem with forced air system is blowouts. Towards the end of their lifespan, the blowers can malfunction and stop working. It’s also not uncommon for cheaper systems to have issues with volume.

Gravity Systems – Gravity systems operate using the principle that cold air sinks, while hot air rises. Therefore, a gravity system cannot be used in conjunction with an air conditioning system. These systems are positioned in the basement. When switched on, the warm air rises through the ceiling and heats your home. When it cools, it sinks down again and is reheated.

Radiant Systems – Radiant systems also come with the same problem as gravity systems. They cannot be used in conjunction with air conditioning systems. A radiant heating system heats the floors, walls, or ceilings of a room. Most commonly, though, they’re used to heat implements like radiators, which distribute heat around your room. The main downside of radiant systems is the pipes used to transport hot water are prone to malfunction, either due to mineral deposits or general wear and tear.

List of HVAC System Parts and How They Work

It’s important to understand the various parts that make up the HVAC system, so you know how they work together. Despite various models having special features, the differences between their core components are comparatively few. There are four main parts to every HVAC system.

- The furnace utilizes natural gas or oil to heat the air. Within the furnace is a heat exchanger, which is the part of the furnace responsible for heating up the air to the right temperature. You’ll typically find the furnace in the attic, basement, or a specially designed closet space.

- The air conditioner cools the air and is found outside of the house. It uses electricity and coolant liquid to reduce the temperature of the air, while sending hot air outside and cold air inside.

- Ductwork is the transit system for hot and cold air throughout the home. It moves it throughout the interior of your home.

- The thermostat acts as the brain of your system. It can turn your system on and off, control the temperature and also operate any other special features that you have installed alongside your system.

Controls for Heating and Cooling Systems

The heart of your heating system is the thermostat. This is heat-sensitive and controls the temperature of your home. It also has the ability to respond to the current air temperature by itself.

The set point is the temperature you set manually as your preferred temperature. If the thermostat notices it is above or below the set point, it will act accordingly, by turning the furnace on or off. The key component is the bimetallic element that contracts or expands when the temperature changes within your home.

If you have an older thermostat, it will have two exposed contacts. When the room cools, the bimetallic element bends. It contacts electronically, before making a second contact. The system activates when the second contact bends, which launches the heating system.

What about modern thermostats, though?

They work differently because the contacts aren’t open to the elements. They’re held behind glass for protection. The contacts uncoil when the temperature drops. Using a series of magnets and a steel bar, the contacts close to complete the electrical circuit when the temperature drops too low.

It works in the exact opposite way when the furnace needs to be switched off.

Modern thermostats are far more accurate than their older counterparts. They’re also more durable because their electrical contacts are held behind glass.

Conclusion

Your HVAC system isn’t as complicated as you might think. It’s simply a combination of a furnace and air-conditioning system. Your thermostat is the brain that controls the way it works.

If you’re thinking about installing a new system within your home, make sure you do your research first. Get quotes from multiple companies and make sure an expert visits your home to inspect the premises. The type of home and the layout of it will influence how much you pay for it.